- Home

- Desktop

- Professional

- Self-Assembly

- Childrens

- Services

- Refills

- Scanners

- Innovations

- Files

Our guide to Printers 3D...

3D printers use computer CAD drawings or digital plans to 'print' tangible three dimensional objects that you can touch and hold in your hand. There are a number of different 3D printing technologies and print media available (some of which are detailed below).

The digital plans that are used to programme them can be created using 3D CAD design programmes such as Autocad, downloaded via the internet, or by scanning an existing object.

The plans for 3D printed objects are either created on a computer using graphic design software, or by 'scanning' an object, with a special type of camera that creates a plan on a computer. The 3D printer then uses the digital plan to print the object.

Glass

Polymers

Wax

Snacks and dishes will be created by syringes injected with edible foods.

Decorating and designing foods with icing and other soft foods of liquid consistency will become possible.

3D bioprinting will allow for the printing of cells placed in predetermined patterns to replicate human tissues, organs and blood vessels.

This may potentially eliminate the need for organ donors.

May provide doctors and surgeons with on-demand human tissue.

It is already making it possible to design and print artificial limbs with customised coverings. The cost of making artificial limbs could be reduced to 1/10 of traditional cost

We are moving from the age of Pre-fabrication, where the products we buy are have already been made and are stocked in a shop or warehouse, to the age of Personal Fabrication, where consumers make personalised items.

It is now possible to produce complicated 3D parts and assemblies made from various materials in a single build. This reduces the need for tooling, machining and handcrafting prototypes.

More efficient designs, design changes, and more effective experimentation Reduces the need to maintain an inventory of physical molds

What materials can you 3D print

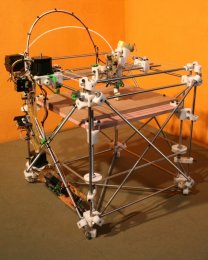

Specifications, prices and designs of 3D Printers vary with some small enough to sit on your desk, and others massive enough to print building components. The materials employed vary as well, with some using molten metal and others printing out liquid concrete. Many combine a variety of materials, enabling the construction of pre-assembled complex objects with moving parts and even integrating electronic components.

Aplications of 3D Printing

These machines have obvious applications in architecture and product design, allowing designers to print complex prototypes at the push of a button, and they are already widely adopted in these industries. However it also has applications in a wide variety of other fields including industrial design, engineering and construction, automotive, aerospace, dental and medical industries, education, civil engineering, fashion, jewelry and footwear, amongst others.

Here are some real-world examples demonstrating the applications:

WASHING MACHINE

In the old days, if the handle on a householder's washing machine broke, they would have to order a new part and wait for it to be delivered. Now, they could go online and download a 3D file, and print a replacement there and then. If they owned a 3D scanner they could scan the object, creating the 3D file themselves.

PHONE COVER

The same principal applies to just about any simple object, like a phone cover, with consumers able to purchase the design online and print them at home. This could revolutionise manufacturing, reducing costs (as shipping, warehousing and shop storefronts are no longer required), and potentially reducing our carbon footprint.

MUSEUM

Museums and art galleries can scan delicate objects in three dimensions and print accurate replicas, to study and display. Visitors to the gallery's website might be able to print out the object, despite being located in a different continent.

HOBBY

The vintage car enthusiast might scan and print rare or discontinued car parts that he or she may have otherwise been unable to obtain. See Jay Lenos 3D printer.

Fused Deposition Modeling (FDM) printers extrude partially molten ABS plastic in extremely fine layers one on top of the other, forming the entire 3D model in a single piece from the ground up. The HP Designjet 3D (pictured above right) is an example of an FDM. Manufacturer Stratasys developed the FDM technique in 1988 and have been at the forefront of 3D printing technology ever since and are currently making Dimension printers.

SLS Printers 3D

Selective laser sintering (SLS) and direct metal laser sintering (DMLS) printers are similar to FDM printers in that they build up successive layers of material (plastic, metal, ceramic, or glass powders) from the ground up, however they use a high power laser to fuse small particles of the material in a granular powder bed, into a mass that has the programmed three dimensional shape. When targetted with the laser the he fine powder is set into a hard, plaster-like finish.

To understand how these machines work, in their most basic form, it is useful to compare them with conventional 2D printers similar to the ones most people will have connected to their desktop computer.

A conventional 2D inkjet printer contains a print-head that is capable of releasing a dot of ink on command. The print-head is moved across a sheet of paper left to right, and gradually front to back, occasionally releasing a dot of ink. Eventually it will have moved across the entire surface of the paper, and the release of the dots of ink will have been timed in such a way that together they combine to make a recognisable picture or text.

Instead of ink, the print-head in a 3D printer releases a blob of plastic (or other material) that stands proud of the paper or printable area. You would be able to feel each dot if you ran your hand across the printable area. The print-head moves across the printable area, in the same way as a conventional printer, but once it has moved across the entire surface, the print head is raised up by a tiny amount and the process begins again. By printing a blob of material on top of the previous blobs, the printer is able to build up three dimensional shapes, a bit like you would build a wall.

Please note, there are a number of different and competing 3D printing technologies, of which the above method is just one simplified example to illustrate the general principle. The main differences are found in the way layers are built to create parts. Some methods use melting or softening material to produce the layers, e.g. selective laser sintering (SLS) and fused deposition modeling (FDM), while others lay liquid materials that are cured with different technologies.

Each method has its advantages and disadvantages. Generally, the main considerations are speed, cost, cost of the 3D printer, choice and cost of materials and colour capabilities.